Belt Systems

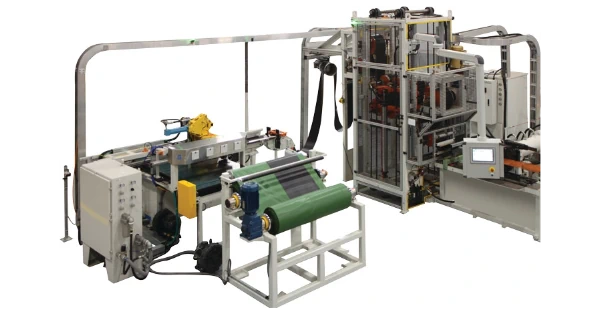

Gain enhanced flexibility and versatility with our proven Steelastic Belt Systems. Maintain precision cord spacing, gauge control and superior overall dimensional stability of steel reinforced rubber belt.

View Belt Systems

Body Ply Systems

The Steelastic Body Ply Systems makes it possible to produce textile body ply material without the use of a calender. Precision extrusion and splicing technology combine to produce premium quality body ply material for your PCR, aircraft or specialty application.

View Body Ply Systems

Cap Strip Systems

The Steelastic Cap Strip System is a highly controlled process delivering precision cord spacing, full cord encapsulation, and no cut cords. The system streamlines your manufacturing process by significantly reducing your capital expense, labor and scrap, while providing greater flexibility in scheduling.

View Cap Strip Systems

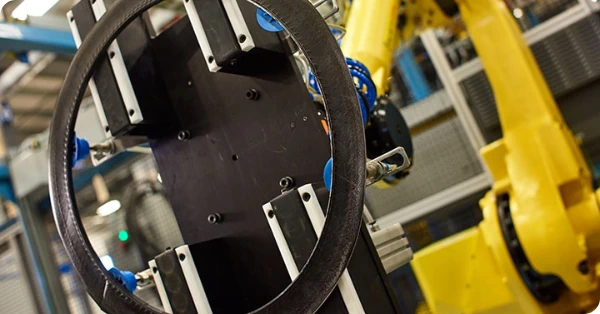

Automatic Apex Systems

The Steelastic Automatic Apex System was the first system developed to automatically extrude, form and apply rubber apex onto a tire bead. The system continues to be enhanced with robotic handling solutions and vision-based inspection technology to meet the tightest quality and throughput requirements of the global tire market.

View Automatic Apex Systems

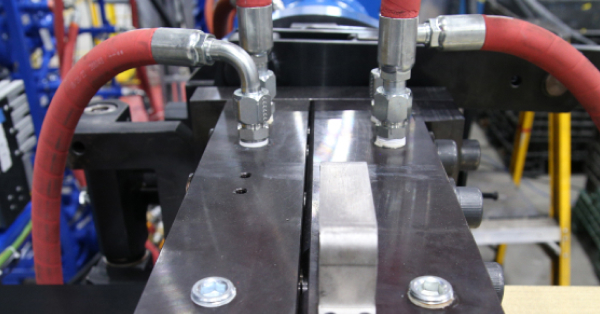

Double Roll Roller Die Hot Gum Edging Systems

The Double Roll Roller Die (DRRD) Hot Gum Edging System is Steelastic’s latest innovation in single compound gum application for steel belts. With this machine, the rubber is extruded via a die into a double roll system to produce highly toleranced gum material. The gum is then slit and applied to the steel belt, either top applied or wrapped.

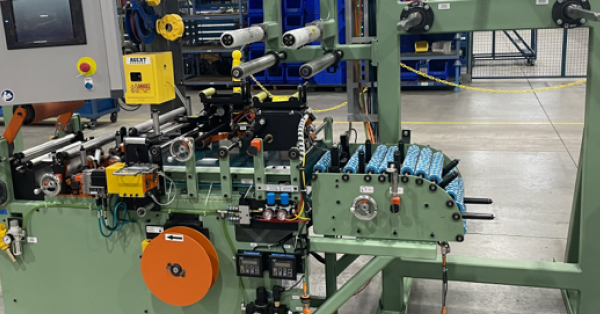

Cold Gum Edging Systems

The Cold Gum Edging System is Steelastic’s latest innovation in single compound cold gum application for both belts and body ply material. With this machine, spools of pre-manufactured cold gum material, complete with polythene liner, are unwound and precisely applied to belt of body ply, either top applied or wrapped.

CordSight Extrusion Thermal Inspection Systems

Take an inside look at extruded steel and textile reinforced rubber with the CordSight Extrusion Thermal Inspection System. This system scans for missing cords, tension abnormalities, and extrusion defects, all with thermal imaging technology. Improve the quality of your tires with the CordSight Extrusion Thermal Inspection System.

Cold Feed Extrusion Spicing Units

The Cold Feed Extrusion Splicing Unit enhances safety and quality by automatically splicing sheets of rubber feedstock. It eliminates the need for operators to use hot knives and significant physical exertion to prepare and interlock heavy and awkward sheets of rubber. The device ensures a consistent and strong splice, with minimal overlap, providing a better quality end product.

Calenderless Tire Manufacturing Cell

Eliminate traditional calendering with our Calenderless Tire Manufacturing Cell. This innovative system streamlines tire production by extruding precise components directly onto building drums, reducing waste and increasing flexibility. Achieve higher efficiency, improved material utilization, and superior quality in your tire component production process.

View Calenderless Tire Manufacturing Cell