Get full cord encapsulation, precision cord spacing and zero cut cords.

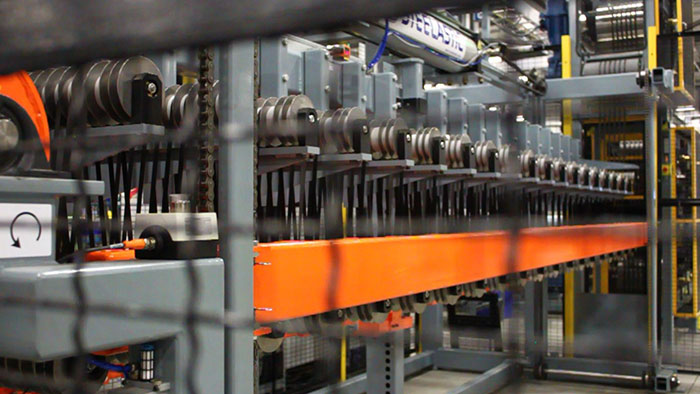

The Steelastic® Extruded Steel/Textile Cap Strip System is becoming the process of choice for tire manufacturers due to quality and efficiency advantages over the calendering and slitting process for:

Advantages of Cap Strip Systems for Calenderless Tire Production

There are many key advantages of the STEELASTIC Extruded Cap Strip System for tire production and component manufacturing.

Significantly Less Capital Investment

Compared to a calendering and slitting system, this calenderless tire production process requires significantly less capital investment. The flexibility of our system, combined with the lower cost to invest, makes productive tire manufacturing more accessible for even small businesses.

Enhanced Productivity

Many of the features of the STEELASTIC Extruded Cap Strip System can lead to increased productivity. With the calenderless system, it eliminates work in process materials and handling and needs only one operator per cap strip system.

Efficient Process

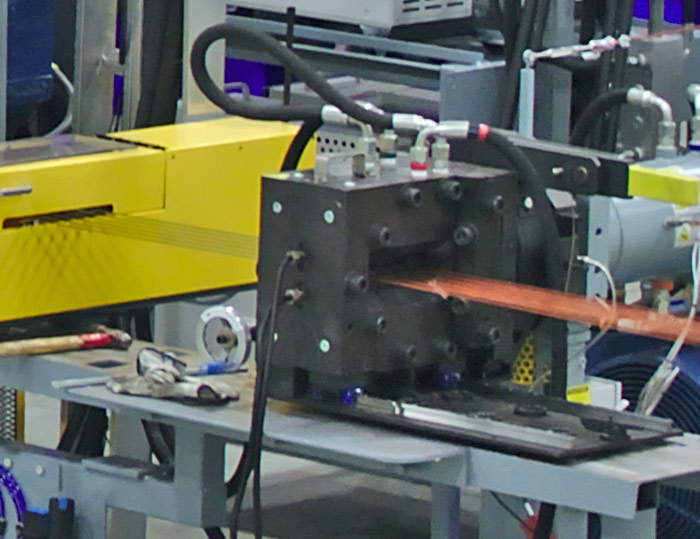

The streamlined process and design of the STEELASTIC cap strip machine makes it a more efficient process. Our calenderless system offers precision cord placement. Full-cord encapsulation means no exposure of cords to the environment and no chance for cut or crossed cords. The STEELASTIC cap strip machine is compatible with polyester, nylon, fiberglass, aramid, steel and other cord materials.

Customization options

The STEELASTIC cap strip system offers a variety of customization options, including:

- Broken cord detection systems

- Screen changer systems

- Strip gauge and width inspection systems

- Customized wind-up systems

- Customized data acquisition systems

Learn More About Our Innovative Cap Strip System

What can a STEELASTIC extruded steel/textile cap strip machine do for your business? Fill out the short form above, and we’ll send you the full data sheet, with more details and exact specifications.