AUTOMATIC APEX MACHINE FOR APEXED BEAD ADHESION

Delivering superior bead adhesion and custom handling of your apexed tire beads

The STEELASTIC® Apex Application System was the first system to automatically extrude, form and apply a rubber apex onto the outside periphery of a tire bead. Since its introduction, the Steelastic bead apex machine has been continually developed to meet ever increasing productivity and quality requirements for:

- Passenger Tires

- Aircraft Tires

- Motorcycle Tires

STEELASTIC® APEX Bead Machine: Key Benefits

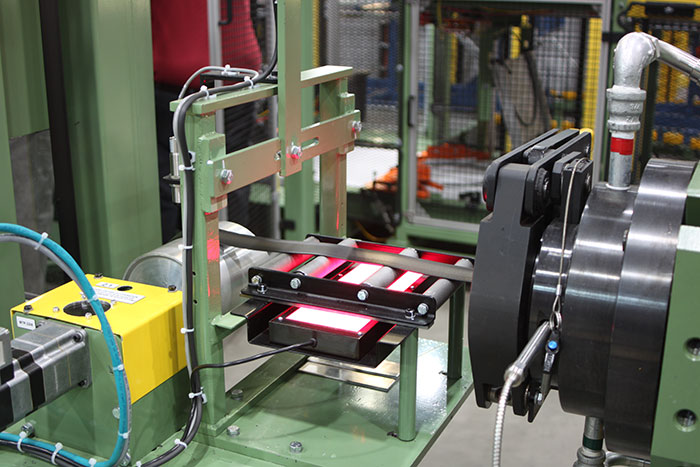

- Stitches both sides of the rubber apex and applies significant downward force producing superior apex bead adhesion

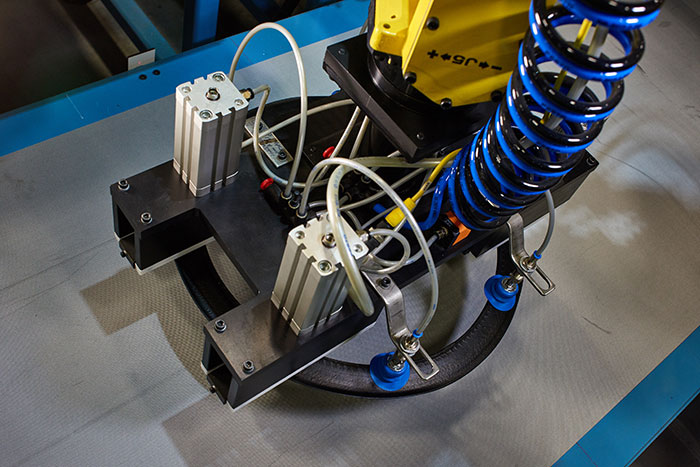

- System is highly flexible and is designed to handle quick changeovers of bead construction, bead diameter, apex geometry, and compound

- Tightly controlled and consistent process yields unmatched splice repeatability

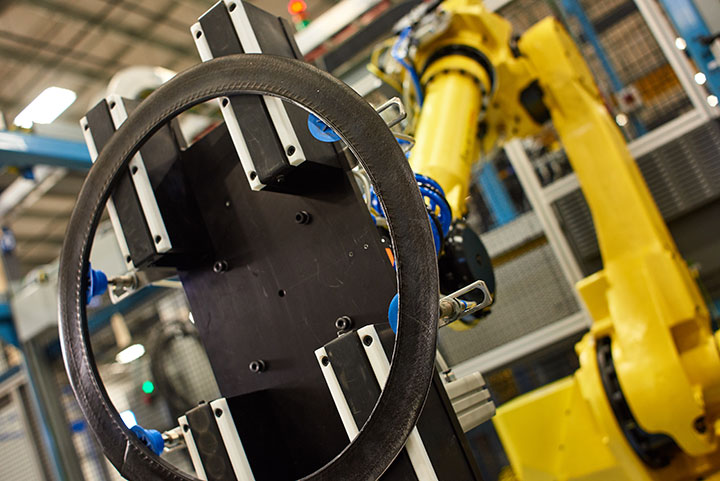

- Customizable system that can handle any single wire or ribbon bead construction

- Cycle times as low as 8 seconds

- Handles apexed bead adhesion for bead diameters ranging 12 to 24 inches

- Requires only one operator per system

- System can produce straight, angled or curved apex profiles

- Robotic and non-robotic unloading options configured to the specific tire plant’s needs

Download the Complete Apex Machine Overview

To learn more about the technical details and advantages, please download the Automatic Apexing Machine PDF Data Sheet.