STEELASTIC® Aircraft Tire Systems

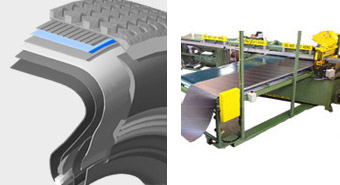

Manufactured in a highly regulated industry, aircraft tires require consistent quality and unmatched precision — two areas where Steelastic excels. Our calendarless tire component preparation systems can be used in the production of general aviation tires, commercial aircraft tires and military aircraft tires.

Our proven, extrusion-based process allows you to produce a very thin gauge with more precision and consistency than a traditional calender, so you can manufacture a low-weight aircraft tire without sacrificing performance. Our unique, combination systems share common creel and extrusion processes to produce multiple product codes using one system.

Beyond our tire component preparation equipment, tire manufacturers also lean on Steelastic’s years of experience and expertise, as they undergo the aircraft manufacturing certification and approval process. Contact us to learn more or request a quote.

Aircraft Tire Manufacturing Systems Include:

Extruded Textile Belt and Ply Systems

Steelastic Extruded Textile Belt and Ply Systems allows you to maintain precision cord spacing, gauge control and superior overall dimensional stability of textile reinforced rubber belt and ply.

View Belt Systems >>

Extruded Textile Body Ply Systems

In aircraft applications, Steelastic’s Extruded Textile Body Ply System combines precision extrusion and splicing technology to create textile body ply material without the need for bulky, expensive calendering equipment.

View Body Ply Systems >>

Extruded Cap Strip Systems

The Steelastic Cap Strip System provides full cord encapsulation. Using a highly controlled process, we have completely eliminated the chance of bare or exposed cords by using precise cord spacing and placement.

View Cap Strip Systems >>