Extrusion systems uniquely developed for the tire industry.

RMS® Extrusion Systems are used to manufacture premium quality components for:

- Passenger Tires

- Aircraft Tires

- Truck & Bus Tires

- Non-pneumatic Tires

- OTR Tires

- Rubber Track

Learn more about what RMS Equipment can do for you as a leading rubber extrusion company below.

RMS® SINGLE ROLL ROLLER DIE (SRRD)

As dimensional tolerances continue to become more critical, conventional extrusion systems become less effective and reliable. The solution to this problem is the RMS Single Roll Roller Die (SRRD) system which combines the flexibility and economy of a simple extruder head with the accuracy and dimensional control of a calender. The result is high-quality stable product that maintains superior dimensional characteristics with absolute consistency.

- Flexibility of a pressure head with the accuracy of a calender

- High degree of flexibility by way of simple, inexpensive, easy-to-change tooling

- Low-pressure process results in reduced compound temperature and increased line speed

- Trim-less die design eliminates scrap and rework

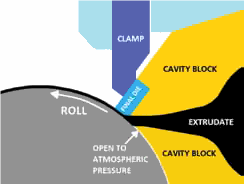

Problem: Most extrusion systems rely on the “push” principle where compounds are forced with high pressure out of the die. Die swell characteristics and high temperatures caused by the high pressures can no longer be tolerated with modern dimensional requirements and production needs.

Solution: RMS has developed the SRRD that uses the “pull” principle. The compound is brought to the roll face where it is exposed to the atmosphere thus eliminating the high pressure of the “push” system. This allows for higher productivity on temperature-sensitive compounds. The “pull” principle uses the roll surface to pull the compound past the shaping die with no die swell. The result is a dimensionally accurate and stable product at a lower cost.

RMS® SRRD: Key Benefits

- Improved dimensional accuracy of extruded flat or profiled components

- Maintains dimensional consistency at different speeds

- Suitable for temperature-sensitive compounds

- Can extrude single compound, multiple components

- Compact and flexible system for production or development applications

- Eliminates die swell due to the pull extrusion principle

- Reduces extrusion temperatures due to lower head cavity pressures

- Enables extrusions to be produced at increased line speeds

- Inexpensive and quick-change (under 1 minute) dies for different products

- Most compounds are able to run trim-less

- Quick and easy head clean out

- Can be used with any cold or hot feed extruder

- Suitable for applications including apex, sidewall components, inner liner and additional components onto an existing line

| RMS® SRRD SPECIFICATIONS | |||||

| Mini-SRRD 200 | Mini-SRRD 400 | SRRD500 | SRRD650 | SRRD800 | |

| Maximum Width of Extrusions: | 8.0” [200mm] | 15.7” [400mm] | 19.7” [500mm] | 25.6” [650mm] | 31.5” [800mm] |

| Minimum Thickness of Strip or Profile: | 0.03” [0.8mm] | 0.03” [0.8mm] | 0.03” [0.8mm] | 0.03” [0.8mm] | 0.03” [0.8mm] |

| Maximum thickness of strip of Profile: | 0.300” [7.5mm] | 0.47” [12.0mm] | 0.47” [12.0mm] | 0.47” [12.0mm] | 0.47” [12.0mm] |

| Maximum Line Speed: | 115 fpm [35 mpm] | 115 fpm [35 mpm] | 115 fpm [35 mpm] | 115 fpm [35 mpm] | 115 fpm [35 mpm] |

INNER LINER ABRASION STRIP / CHAFER APPLICATION

Enables precise application of extruded strip onto inner liner. These systems can be easily retrofitted to existing inner liner production lines.

- Application of extruded strips to hot inner liner.

- Typical System Comprised of the following

(sizes to be determined based on the required profile cross section):

(1) One mini single roll roller die

(1) One closed loop, servo-actuated strip positioning system.

(1) One Custom support mezzanine and extruder feed (dictated by customer’s inner liner system).

(1) One Extruder feed system.

(1) One 4-5 Zone TCU system.

(1) One Turnkey control system (Roll speed slaved to match the existing line speed.)

| RMS® INNER LINER ABRASION STRIP / CHAFER APPLICATION SPECIFICATIONS | |

| Line speed | 0-115 fpm [37 mpm] |

| Overall width of the finished product | To be specified |

| Strip Qty x Width x Thick | To be Specified |

| Notes: • Actual outputs are dependent upon compound properties. • Motor size may vary depending on the application. • All extruder specifications are for the RMS standard extrusion systems. Specifications may change depending on specific requirements (ie. L/D ratios; motor sizes; screw speeds; & reducer ratios) • Customized modifications available depending on application. |

|

Looking for more from RMS? Learn about rubber extruders by RMS Equipment.