STEELASTIC® Truck / Bus Radial (TBR) Manufacturing Equipment

![This image shows extrusion-based calendlerless tire manufacturing equipment, specifically designed for the truck / bus radial (TBR) market.]](https://www.steelastic.com/wp-content/uploads/tbr-header-3-334x130.jpg)

Commercial truck and bus radial (TBR) tire manufacturing plants are evolving, as the market shifts to lighter, more fuel-efficient tires. Steelastic’s TBR tire component manufacturing equipment provides the flexibility to produce the increasing large number of SKUs for today’s TBR tires.

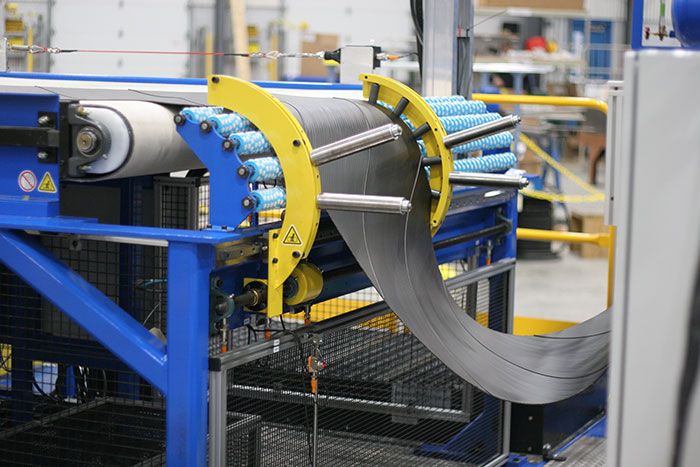

Our extrusion-based systems for TBR tires produce steel belt, steel and textile body ply, and steel and textile cap strip. Unlike the traditional calendering and offline processing equipment, all of our systems are one process from creel to wind-up, eliminating additional handing, and storage.

Our systems are highly automated, reducing operator dependence and labor costs at your manufacturing facility. Our systems permit very quick changes in cord, compound, and finished material specifications, providing the flexibility demanded by todays multi-SKU tire market. Contact us to request a quote for your TBR tire component manufacturing equipment.

TBR Tire Component Manufacturing Equipment:

Extruded Steel Belt Systems

Steelastic’s Extruded Steel Belt Systems maintain precision cord spacing, gauge control and superior overall dimensional stability of steel belt – a critical requirement for truck / bus radial (TBR) tire manufacturing.

View Belt Systems >>

Extruded Steel & Textile Body Ply Systems

Using our proven extrusion, cutting and splicing technology, Steelastic’s Extruded Steel and Textile Body Ply Systems enable tire manufacturers to produce steel and textile body ply material for truck / bus radial (TBR) tires without a traditional calendering and offline processing equipment.

View Body Ply Systems >>

Extruded Textile & Cap Strip Systems

Steelastics Textile and Steel Cap Strip Systems provide precision cord placement, full cord encapsulation and eliminate the possibility of cut or exposed cords. This highly controlled process ensures the highest quality of cap strip material for your truck / bus radial (TBR) tire production/

View Cap Strip Systems >>