Steelastic Strip Gauge Monitoring System

Control quality with the Steelastic Strip Gauge Monitoring System. Mounted between the die head exit and cooling drum entrance, this system uses a single-point laser measurement system that continuously traverses back and forth across the extruded strip to verify the average gauge. This upgrade will provide an audible and visual alarm, if your product is verified to be out of specification.

Steelastic Cooling Drum Accumulator

Minimize your production downtime and produce belt or body ply more efficiently with a Steelastic Cooling Drum Accumulator. With this upgrade, your cooling drum continuously accumulates material, while you adjust your downstream operations, allowing you to complete spool changes or tooling changes without having to stop your extruder.

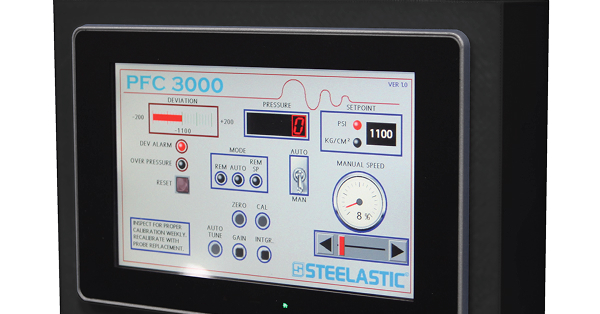

Steelastic Pressure Follower Controller

Upgrade your legacy pressure follower controller (PFC) system with our new and improved digital controller. This new system uses state of the art PLC-based technology integrated with a touchscreen to control extruder screw speed to maintain pressure with a PID control loop. The system is designed to interface with existing PLC controls and sensor technology to ensure that field upgrades are fast and efficient. The system is pre-programmed and includes all IO capabilities.

Automatic Belt Width Adjustment Tooling

Avoid unnecessary downtime when you upgrade your existing standard vacuum foot top plate with this direct replacement. Our automatic belt width adjustment tooling allows you to change the width of your belt in only 5 seconds with the push of a few buttons. With this upgrade, vacuum loss is limited through restricted orifice holes and you maintain high holding force closer to the cut edge.

Custom Tire Component Retrofit & Rebuilds

Multiple variables impact the lifecycle of your Steelastic systems. Your material type, compounds and run time all influence your machine’s ability to maintain productivity. But small investments in tire component retrofits and rebuilds can provide a large pay-off for your tire component production. Whether you need a single module retrofit or a full system rebuild, we can create a customized solution to help extend the lifespan of your machinery and improve the quality of your tire component manufacturing. To get started, contact us to schedule a .