The Revolutionary Bead Apex Inspection System

Tire manufacturers have long sought the ability to ensure precise uniformity and defect-free apexed beads prior to passing these components through to the tire-build process.

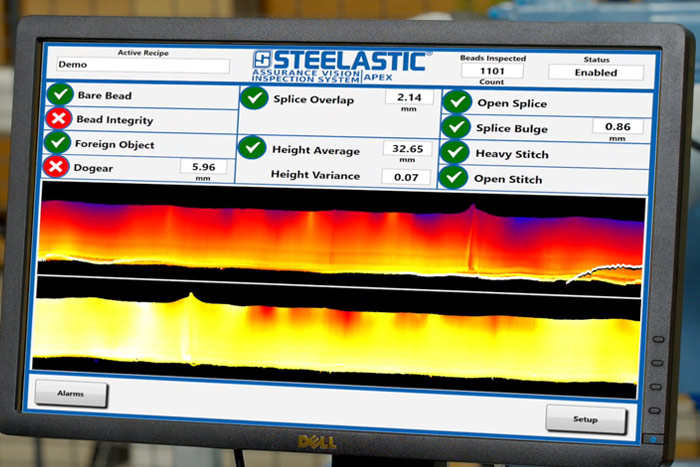

Visual inspection by operators and even single-spot camera inspections can allow loose, frayed or badly stacked bead wires, dog-eared apex or bad splices to be passed through to tire building machines.

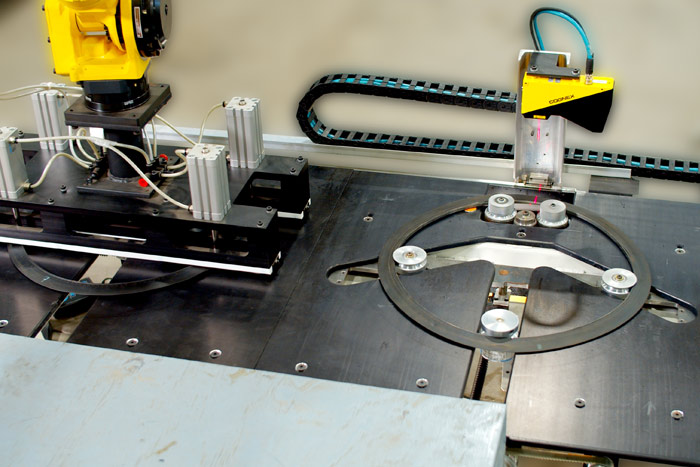

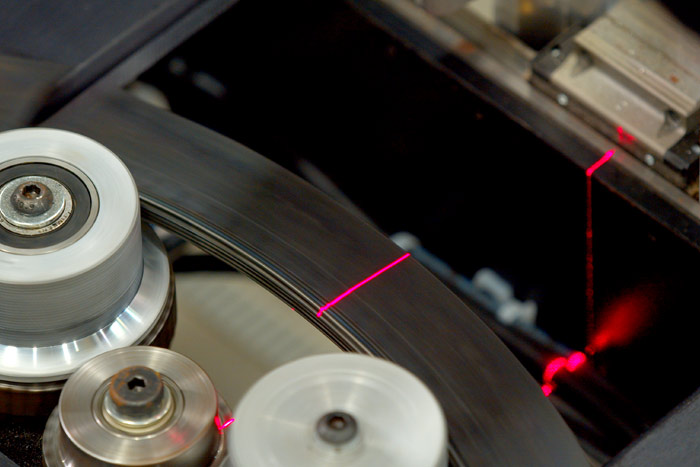

Introducing Steelastic’s 360 Degree, 2-sided automatic and traceable bead apex inspection system.

Both sides of the entire circumference of apexed beads are visually scanned for up to 12 possible defect anomalies. Inspected assemblies are automatically carted continuing to tire building machines or separated for apex re-work.

Recognizing defects at this stage allows for bead apex failures to be re-worked. This eliminates unnecessary costs of scrap tires due to defective apexed beads – or worse – an imperfectly manufactured tire which is ultimately placed on a vehicle.

Eliminate operator-centric, visual inspection and the possibility of defectively formed bead apex assemblies passing through. Using automatic apexing machines combined with 360 Degree Inspection system from Steelastic, you can achieve up to 99% thoroughly evaluated bead apex through-put.

Provide OEMs with traceable, and cart-specific bar-coded documentation of all bead apex assemblies along with visible, photographic documentation of assembly integrity.

Interested? Contact Steelastic today for a demonstration!

Related Documents