STEELASTIC® Passenger Car Radial Tire Systems

As more passenger car types enter the market and the industry shifts to electric-powered vehicles, a larger variety of tires is needed – such as steel belted tires. As tire manufacturers search for new ways to develop lighter, performance-based components to extend battery life, Steelastic offers PCR systems designed to help you maintain pace with the evolving industry.

Our PCR tire component systems can outfit your new manufacturing plant or add capacity to your existing facility. Our continuous, extrusion-based process seamlessly integrates with your existing production line, allowing you to meet growing product demands without the need to overhaul your existing capital equipment.

Discover how Steelastic steel belted radial tire systems can lower your labor costs, reduce your scrap material and boost your productivity. Contact us to request a quote.

PCR Manufacturing Systems Include:

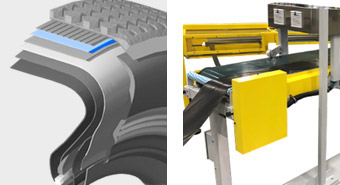

Extruded Radial Steel Belt Systems

Steelastic Extruded Radial Steel Belt Systems provide enhanced flexibility and versatility. Maintain precision cord spacing, gauge control and superior overall dimensional stability of steel reinforced rubber belt.

View Belt Systems >>

Extruded Textile Body Ply Systems

With the Steelastic Extruded Textile Body Ply System, it’s finally possible to produce textile body ply material without the use of calender. Precision extrusion and splicing technology combine to produce premium quality body ply material for your PCR application.

View Body Ply Systems >>

Extruded Cap Strip Systems

The Steelastic Cap Strip System is a highly controlled process the delivers precision cord spacing, full cord encapsulation, and no cut cords. The system significantly reduces capital expense, labor costs and scrap material, while offering greater flexibility.

View Cap Strip Systems >>

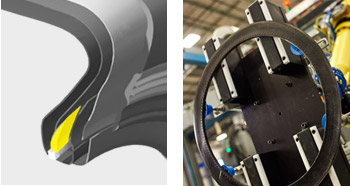

Automatic Apex Systems

The Steelastic Apex Application System is the first system developed to automatically extrude, form, and apply rubber apex onto a tire bead. The system’s robotic handling solutions and vision-based inspection technology meets the tightest quality and throughput requirements of the PCR tire market.

View Apex Systems >>