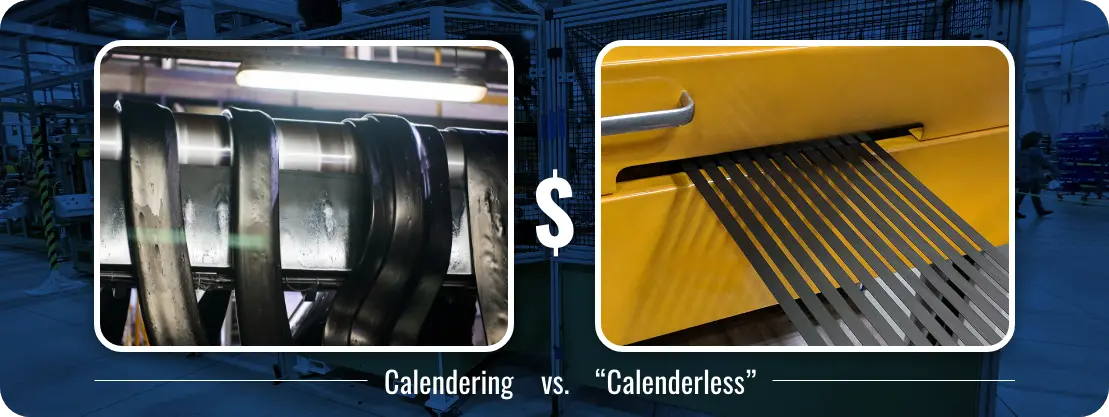

A capital investment in tire manufacturing equipment is no small purchase. Whether you’re just starting a tire production business or upgrading your equipment, it’s always worth comparing a traditional calender vs. calenderless tire production process. In this blog, we’ll explore the TCO, or total cost of ownership, of calender equipment vs calenderless equipment.

How Do You Determine Total Cost of Ownership?

To calculate the true total cost of ownership for calender and calenderless equipment, it’s essential to know the life span of the machine. Both calender and calenderless equipment generally lasts 30 years. This assumes that both machines are receiving. This assumes that both machines are receiving adequate preventative maintenance.

Capital Expenses

Without question, capital expenses are some of the biggest investments you’ll make for your tire manufacturing business. Whether it’s an equipment or building expense, we’ll help you know what is required for both a traditional calender and a calenderless tire manufacturing process.

Equipment Expenses: Calender vs. Calenderless

The calender and calenderless tire manufacturing process is very different, requiring a different set of equipment. (You can read more about the differences in this blog.) The chart below compares the capital equipment required for both processes.

| Calender Solution | Calenderless Solution |

|

| Textile Fabric Letoff (60" Wide) | Yes | Not Required |

| Textile Body Ply Creels (qty 2 minimum) | Not Required | 264 Spools |

| Steel Belt Creels (qty 2 minimum) | 1449 Spools | 240 Spools |

| Cap Strip Textile Creels (qty 2 minimum) | Not Required | 152 Spools |

| Pre Calender Accumulator | Yes | Not Required |

| Extruder, TCU & Die Head | Not Required | Required for Steel Belt, Body Ply, & Cap Strip |

| 4 Roll Calender Line for Both Textile and Steel Cords | Yes | Not Required |

| Cooling Drums | Yes | Yes |

| Windup (60" Wide) | Yes | Not Required |

| Steel Belt Cutter w/ Belt Edge Application, Double Windups | Yes | Yes |

| Slitter with 2 x Double Windups for Above | Option Available | Option Available |

| Ply Cutter w/ Cold Strip Application, 2 x Windup | Yes | Yes |

| Cap Strip System w/ Cooling Drums, Accumulator, up to 20 Windups | Yes | Yes |

| Wide Slitter | Yes | Not Required |

| Mini Slitter | Yes | Not Required |

| Rubberized Calender Material Pallets/Cassettes | Yes | Not Required |

| Steel Belt Cassettes | Yes | Yes |

| Textile Ply Cassettes | Yes | Yes |

| Slitter Pre-Cut Carts | Yes | Not Required |

| Cap Strip Racks | Yes | Yes |

See for yourself … which requires less equipment? The answer: calenderless.

Building Expenses

If you’re building a factory for your tire manufacturing process, you’ll want to consider warehousing and foundation needs, as well as the cost of integrating utilities such as electricity, cooling water, steam and compressed air. Because a calenderless system does not use steam, it’s one less utility system to integrate into the building requirements.

When all is said and done, it is cheaper for small tire manufacturers to invest in a building that houses a calenderless system.

Operational Expenses

Now, let’s explore the on-going operational expenses required of calender and calenderless tire manufacturing. In this section, we’ll look at the energy requirements, human resources and training and maintenance and repairs.

Utilities & Energy Required

While the cost of installing utilities was documented above, it’s important to factor in the annual cost of the electricity, cooling water, steam and compressed air. Which process uses less energy? It depends. The calenderless tire manufacturing process uses less electricity and steam than the traditional calender process. However, businesses that choose the traditional calender process often consume less cooling water and very little compressed air.

Considering the aggregate cost of energy and utilities expanded over the millions of tires produced, the calenderless tire manufacturing process costs less.

Human Resources & Training

Tire manufacturers know the frustration of losing good employees and the challenge of training new ones. The traditional calender process requires multiple workers, but the calenderless process requires only one – allowing manufacturers to utilize workers more efficiently in other parts of the plant.

Additionally, the training time for the calender tire manufacturing process requires 24 months, while the training process for the calenderless process is only six months.

When it comes to human resource expenses, including the number of workers and their training, the answer is clear: calenderless tire manufacturing is most cost-efficient.

Maintenance & Repairs

ROI

Here’s the bottom line: After considering all of these factors, calenderless tire manufacturers will meet their ROI goals faster than tire manufacturers using the traditional calender method. When using the calenderless method, tire manufacturers who produce two million tires per year will recover their ROI in just seven years, as opposed to eight years for a traditional calender process. Contact Steelastic to provide a ROI comparison using their Calenderless Tire Plant Model calculator that uses industry standard values or your specific production and cost data.

Request a Quote

Are you ready to revolutionize your tire production process? Request a quote for Steelastic’s calenderless tire equipment. Boost efficiency, reduce downtime and unlock design possibilities. See it in action at our manufacturing facilities. Let’s shape the future of tire manufacturing together. Contact us now.