Are you facing challenges as the tire market continues to evolve? At Steelastic we have supported the tire manufacturing industry for more than 50 years and understand the unique pain points that tire manufacturers encounter. That’s why we’ve developed innovative tire manufacturing solutions to address these problems and help your business thrive.

Let’s explore five common manufacturing issues that Steelastic can help to solve:

1. Managing Inventory

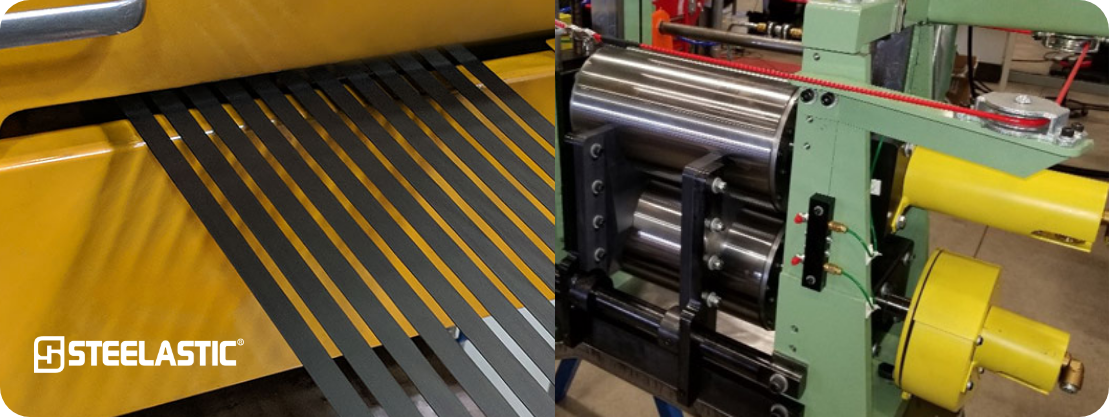

Managing inventory of ever-increasing tire SKUs can be a challenge for tire manufacturers. With Steelastic’s calenderless, extrusion-based system, you gain the flexibility to respond quickly and efficiently to changing customer requirements.

Our extrusion-based tire manufacturing equipment gives you the ability to produce smaller runs, quicker. With Steelastic, you can quickly adapt and adjust your production to meet market requirements, reducing the risk of excess and obsolete inventory. By choosing Steelastic, you can streamline your operations and ensure that your tire inventory remains optimized and aligned with customers needs.

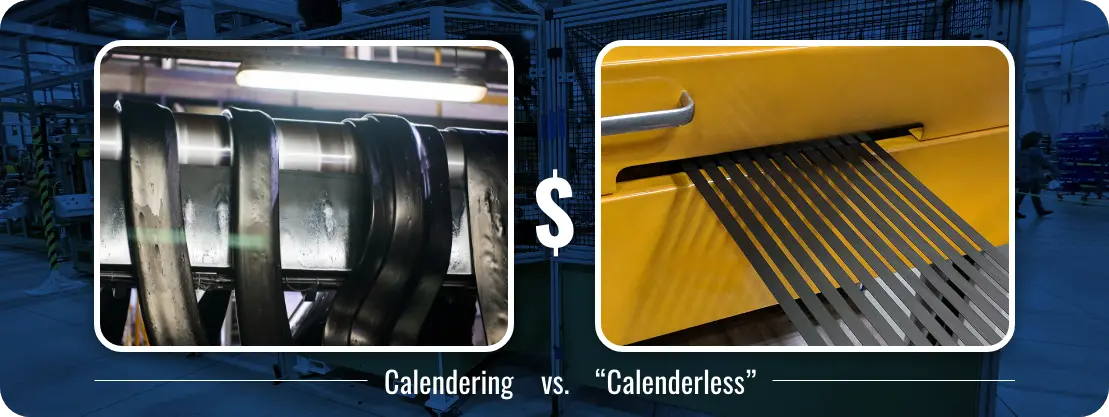

2. Aging Calendering Equipment

If your calendering equipment is aging, you may be faced with expensive and time-consuming upgrades. At Steelastic, we provide a calendering machine alternative, which are extrusion-based systems that provide a quick return on investment (ROI). With our advanced technology, you can replace outdated calendering, and offline processing equipment, with state-of-the-art solutions that offer enhanced flexibility, efficiency, and ease of operation.

Say goodbye to costly repairs or replacements and embrace the benefits of calenderless tire manufacturing equipment, which have significantly lower total cost of ownership (TCO), and increased flexibility, when compared to traditional calendering methods.

3. Insourcing of Tire Components

If your tire manufacturing plant is struggling with limited warehouse space while insourcing tire calendered material, it’s time for a change.

Steelastic’s extrusion-based tire manufacturing equipment has a smaller footprint, increased flexibility, and more tailored production output when compared to traditional tire calendering methods, making it perfect for transitioning to manufacturing tire components in-house. By choosing Steelastic, you can optimize your space utilization and say goodbye to the inventory challenges that come with insourcing calender rolls. Our calenderless, extrusion-based equipment helps turn inventory more quickly, allowing you to align production with customer demand effectively.

4. New Tire Plant Start-Up

Are you considering building a new tire manufacturing plant? Starting a tire plant requires careful consideration of capital investment and the need for a justifiable ROI. Leading tire manufacturers are increasingly choosing Steelastic’s equipment to manufacture their tire components in new plants. And for good reason.

Our technology offers a cost-effective solution that delivers fast returns on investment (ROI). With Steelastic, you can kickstart your new tire manufacturing plant and build capacity in a modular fashion, adding capacity incrementally as production demand increases. Tire manufacturers see this as a significant differentiator versus the calendered alternative, where initial capital outlay, and production capacity can far outweigh requirements.

5. Your Tire Manufacturing Plant Can’t Keep Up

Is your tire manufacturing plant struggling to meet increasing production demand and ever-increasing SKU requirements? At Steelastic, our calenderless, extrusion-based systems are the solution you’ve been searching for. Our equipment provides the ability to grow modularly, allowing you to quickly expand your production capacity and keep pace with market demands.

Our extrusion-based tire component equipment is known for its streamlined efficiency and flexibility. At Steelastic, we’re proud to provide tire manufacturing equipment that outperforms the limitations of traditional calendering processes, ensuring that your plant can keep up with the ever-growing demand for tires.

Reach out to Steelastic

At Steelastic, we understand the challenges that tire manufacturers face. With our industry-leading equipment, you can overcome these pain points and experience increased efficiency, profitability, and customer satisfaction. Contact us today to schedule your free trial run in our facility in Cuyahoga Falls, Ohio. Discover how Steelastic’s solutions can transform your tire manufacturing business. Together, let’s drive towards success.