As industry leaders in tire manufacturing technology, Steelastic’s tire experts are often the first to identify industry trends and provide solutions that improve quality and efficiency. One example is the gum edging process.

Gum edging is nothing new, but it hasn’t always been a required component. As more tire manufacturers receive specifications for gum edging, they’re realizing that their existing systems may not be meeting the needs of today’s steel-belted tires.

Small Component, Big Ramifications

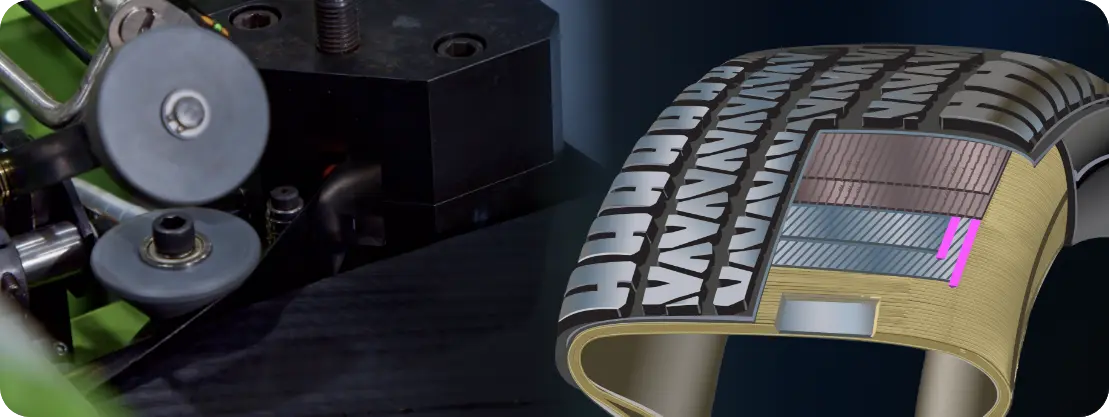

Gum edging is the rubber strip that adheres to the edge of a tire’s steel belt. The rubber strip, or gum edge, protects the steel from friction that creates heat, causing undue wear and tear on the tire. Increasingly, tire manufacturing specifications require the addition of this gum strip to minimize the risk of friction in steel-belted tires.

Due to the industry requirements of increasingly thinner steel belts, existing legacy equipment struggles to apply gum edge without stretching the product out of conformance, apply the gum to the required placement specifications, and complete this process without decreasing the production output speed to accomplish this process.

“It’s a small component that has big ramifications for the industry,” said Bob Irwin, Steelastic’s Vice President of Sales and Marketing.

Adding a Quality Gum Edging System

Steelastic’s gum edging system, developed in 2019, has proven to be the perfect solution for today’s tire manufacturers, who are coping with increased gum edging requirements but lack the equipment to meet these specifications efficiently.

Tire plants can incorporate Steelastic’s gum edging system into their current rubber extrusion system, or they can replace their existing auxiliary equipment on large cutter lines with faster and more efficient equipment with integral gum edging. This allows flexibility for the tire production plant, increasing tire quality and production efficiency as the plant grows.

By incorporating Steelastic’s gum edging system, tire manufacturers (especially tire technology leaders) can deliver a higher-quality product in less time. It’s all part of Steelastic’s calenderless revolution, providing flexible equipment that adjusts to your needs while keeping costs low—and output high.

Reach Out to the Tire Experts

If you’re looking to improve the quality of your tires, explore Steelastic’s gum edging system. To visit our facilities and see the gum edging system in action, contact us today.