In tire manufacturing, each component plays an important part in the overall performance and quality of the finished product. Apexing, however, plays one of the most important parts. Without proper apexing, the tire is at risk for a number of serious problems, from visual defects to structural problems including rim slip, instability and ultimately tire failure.

Steelastic has extensive experience in developing superior apexing solutions to improve tire quality and ensure a safe driving experience.

What Is Apexing for Tires?

Tires are complex products, involving multiple layers that are designed and engineered to withstand the vehicle load while transmitting torque and maintaining road contact. In addition to the well-known tread and sidewalls of the tire, the bead and apex provide true support and stability.

The bead of a tire is the main part that holds your tire to the rim. It bears all of the force on the rim of the tire, which is why it’s reinforced with steel. The apex is the part of the bead that holds it to the tire. The apex is typically fabricated from a rubber compound that encases the steel cord of the bead and attaches it to the tire.

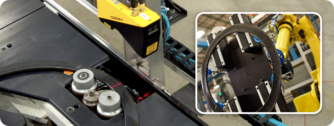

Apexing machinery systems can deliver the most efficient method of apexing tire beads. The best systems, such as Steelastic’s automatic apexing machines, balance flexibility, consistency, quality and production uptimes.

Why Apexing Is Critical

The apex is the most critical piece in tire construction. As the component that distributes stress and provides dynamic stiffness, it prevents the tire from blowing out and maintains the relationship between the bead and the sidewall.

The apex is important, but so is the apexing process. Building the bead-apex combination involves extruding a customized profile, which is then stitched to the bead and then is built into the tire.

Solving Apexing Problems

If at any point there are defects during the tire apexing process, those defects can cause problems in the finished tire, which can create dangerous situations in real-world applications in which the tire is involved. Bead apex quality assurance is critical to apexing outcomes as it can identify defects or production errors before the component is transferred to the tire production facility.

Steelastic’s 360-degree bead inspection capabilities provide a 99% pass-through rate for quality assurance.

How To Improve Your Tire Apexing

There are a couple of ways to improve your tire apexing. The first is application; the second is inspection.

During bead application, vertical stitching means there’s no limit to apex height, as there is with horizontal application. Vertical application allows for taller apexes, which also enables the use of angles and helical shaping for increased stability against gravity.

Another way to improve tire apexing is to make use of additional stitching. When you stitch the bead on both sides, as opposed to only one side (as horizontal applications do), you can significantly increase downward pressure, resulting in better apex bead adhesion. This will create a superior product.

Studies have shown that increased automation during the apexing process, such as during cutting and application, results in improved performance and drastically reduced downtime.

In addition to application, apex bead inspection is a critical part of the process, as this allows defects to be identified and rectified immediately. A 360-degree bead apex inspection will be the most effective method for detecting splice deviations, multilateral apex defects, loose wires, poor stacking and adhesion quality.

Revolutionize Your Manufacturing

Steelastic offers automatic bead apexing machines that ensure superior adhesion and flexibility within a small footprint, featuring industry-leading, dual-sided laser vision bead inspection. Interested in learning how we can customize a solution that meets your needs? Start a conversation.