Since 1970, the Steelastic Company has been moving the world forward with tire technology. We offer most of the equipment you need for tire component manufacturing, offering products for both the traditional calender and calenderless manufacturing.

What is ‘calenderless’ tire manufacturing?

Calenderless tire manufacturing combines principles of lean manufacturing with the latest tire technology. Traditionally, tire manufacturers rely on calendaring to process their rubber into components that can be used for tire construction.

As time and technology progress, some things change. And that can be a good thing.

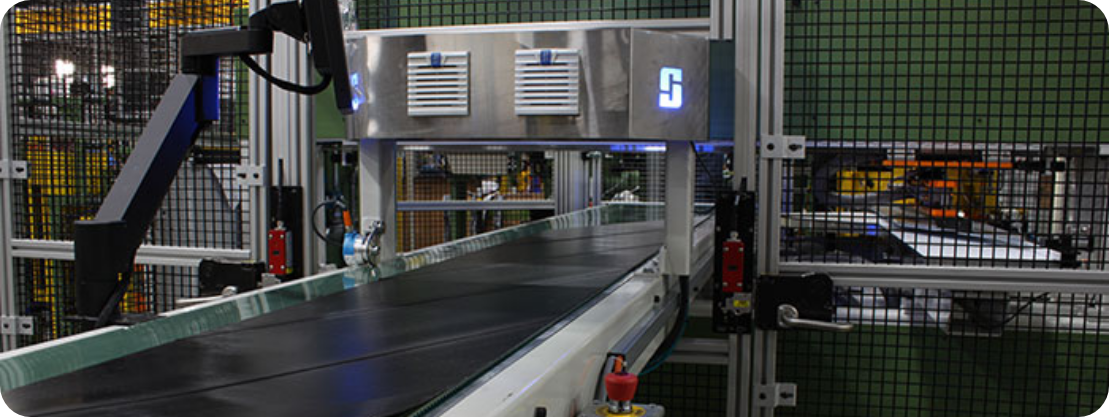

Steelastic’s calenderless tire manufacturing system is an extrusion-based system that produces belt/breaker, body ply, cap strip, inner liner, sidewall, tread, and bead apex. But what’s so great about going calenderless anyway?

The Pros of a Calenderless Tire Manufacturing System

Reduced Wastage

A calenderless system allows tire manufacturers to produce shorter runs of various tire types and sizes. This reduces waste, as it allows tire manufacturers to produce different types of tires, without wasting resources for a longer run on the manufacturing line.

Lower Cost

When waste is reduced, it lowers the overall manufacturing costs and increases net profits.

Additionally, when companies go calenderless, they no longer need expensive and bulky calendaring equipment or off-line processing equipment.

Increased Efficiency

A calenderless system is a more efficient use of resources, time and labor. As an automated process, it reduces labor costs, and cycle time, while increases production capacity so you can hit your goals for manufacturing and profit margins.

Increased Quality Control

Traditional calendaring requires precise measurements on large production volumes that are difficult to obtain. Using a calenderless system inherently reduces the complexity of the system and ensures the highest quality for your tire manufacturing company.

Complexity of System

A calenderless tire manufacturing system is a single cell operation. Raw materials are input into the system and finished tire component preparation materials are produced. While it has a smaller footprint and requires less overall equipment, it is not a simple machine. However, the complex nature of a calenderless system is much less than that of the calender solution. First of all, the calenderless equipment can be supplied in two thirds of the time frame of the calendered solution. Also, operators can be training to be experts is months as opposed to years. However, at Steelastic, we understand that our customers still need our support and that’s why we offer 24/7 service support that is available on the phone, online or in-person, and strategically placed around the globe to offer support when you need it most.

The Cons of a Calenderless Tire Manufacturing System

Large Capacity Tire Production Requirements

The calenderless system cannot match the production volume capabilities of a calender system. The calender process is capable of mass producing a singular specification material at a very high rate. This tends to lead to a slight advantage to calendered solutions on facilities that produce more than 6-7 million tires per year.

Initial Cost of Installation for large volume plants

Every change in manufacturing systems has a cost, or investment, depending on how you look at it. While a calenderless tire manufacturing system is costly, we think that the efficiency and flexibility gained makes it a worthwhile investment in the future of tire manufacturing.

Schedule a Free Trial

Are you interested in learning more about the benefits of calenderless tire manufacturing? See it firsthand at our headquarters in Cuyahoga Falls, Ohio. We will show you our calenderless manufacturing system, so that you can conduct trials to produce tire components to your own specifications. After the trial, we will pack and ship the components to your facility for tire building, testing and validation. Schedule a trial >>