Elevate your Premium Tire Quality with Steelastic’s Extruded Textile & Steel Cap Strip Systems

The Steelastic® Extruded Textile & Steel Cap Strip Systems are fast becoming the preferred choice for premium tire manufacturers. This is due to its major quality and efficiency advantages of extrusion-based systems over the traditional calendering and slitting processes for cap strip, for the following tire types:

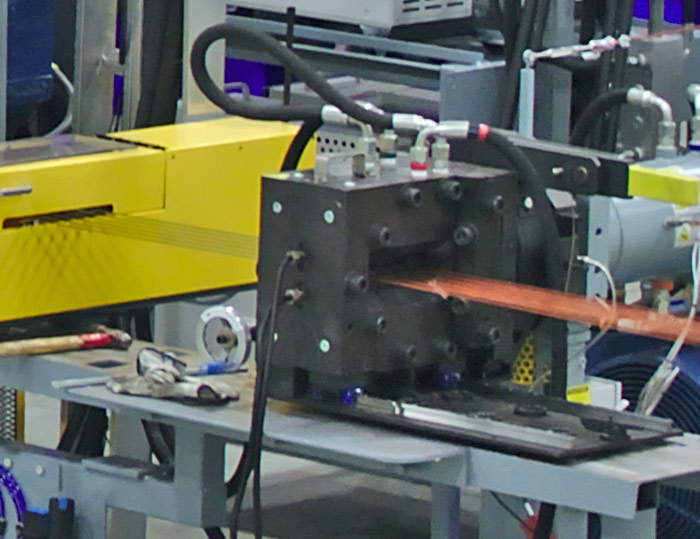

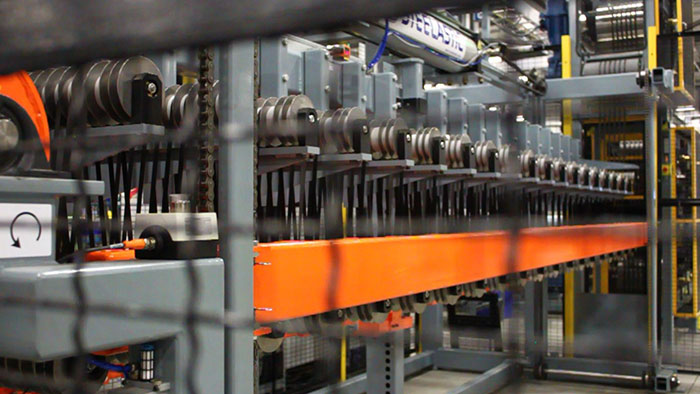

Steelastic’s extrusion-based cap strip system works by extruding rubber to fully encapsulate textile or steel cords into continuous strips of cap strip material. This material is then applied above the steel belt layer, and below the tread, during the tire building process for many types of premium & electric vehicle (EV) tires.

Advantages of Steelastic Extrusion-based Cap Strip Systems

Steelastic’s Extruded Textile & Steel Cap Strip Systems have major quality and efficiency advantages over the traditional process of calendering and slitting of textile and steel cap strip material.

A Higher Quality Cap Strip Product

EV and Premium tire manufacturers are now insisting on the extruded process for their OE and replacement tires due to the marked quality benefits. Here’s why:

- Full rubber encapsulation of cords prevents humidity ingress to textile material which can happen when calendered material is slit.

- No possibility of cut cords, as experienced when slitting calendered material

- Extremely precise cord placement achieved through Steelastic’s precision die tooling and extrusion process.

- Elimination of multi-stage process to calender, handle, slit and wind-up cap strip material.

- Compatibility with polyester, nylon, fiberglass, aramid, steel and other cord materials.

Other Benefits of Steelastic’s Extrusion-based Cap Strip Systems

Compared to a calendering and offline slitting systems, Steelastic’s extrusion-based cap strip production process provides the following additional benefits:

-

Significantly lower capital investment

-

Much smaller overall footprint

-

Lower running costs

-

Elimination of WIP through a one stop process from creel to wind-up

-

Only one operator required per machine

Customization options

The STEELASTIC cap strip system offers a variety of customization options, including:

-

Tension controlled creels with broken cord detection

-

Manual and automatic screen changing

-

Gear pump to increase line speed

-

Hydraulic opening and closing E-Dies

-

Strip gauge and width inspection systems

-

Customized wind-up systems, including auto-changeover and robotic loading / unloading functionality

-

Customized data acquisition systems

Learn More About Our Innovative Cap Strip System

What can a STEELASTIC extruded steel/textile cap strip machine do for your business? Fill out the short form above, and we’ll send you the full data sheet, with more details and exact specifications.