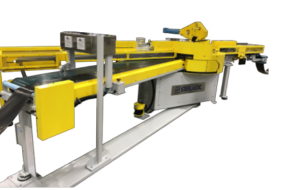

With STEELASTIC’s range of steel belt machines, businesses have a manufacturing process that is fully aligned with changing market needs for lower capital investment, multi-SKU capability, high levels of automation and traceability, reduced utility usage, and ease of operation.

Steelastic’s range of Classic Extruded Steel Belt Systems can produce steel belt & breaker for the following tire types:

- Passenger & Light Truck Tires (PCR & LT)

- Truck and Bus Tires (TBR)

- Off the Road Tires (OTR)

- Aircraft Tires

- Non-Pneumatic Tires

- Rubber Track

Superior quality advantages over alternative manufacturing methods:

- Precise belt width, gauge and edge straightness

- Highly accurate splice and belt angle

- Shortest compound heat history

- Precise cord placement with NO possibility of crossed wires

Why Use an Extrusion-Based Calenderless Steel Belt System?

There are many reasons to use a calenderless system when manufacturing steel belt / breaker:

Ultimate Flexibility

Our extruded steel belt systems allow for changes in finished belt angle, and width, in a matter of seconds. Changes in steel cord and compound can be achieved in under 20 mins. This provides the very high levels of flexibility demanded in the modern tire market, as the tire SKU count continues to rise.

Productivity

A single STEELASTIC extrusion-based steel belt system can manufacture over 4,000 PCR steel belted tires per day, of multiple different SKUs. Typically, two, three, or more systems are operated together, providing tire manufacturers with the perfect mix of high productivity and flexibility.

One Streamlined Process

Our extrusion-based systems are one complete process from creel to wind-up. This eliminates the need to handle and store semi-finished material as required by calendering and offline processing methods.

Enhanced Quality Control & Traceability

STEELASTIC Extruded Steel Belt Systems include a range of vision, thermal and laser product inspection technologies to ensure the highest quality product, along with full traceability to plant manufacturing systems.

Specifications:

- Steel Cord Gauge: 0.02” – 0.1” (0.5mm – 2.5mm)

- Extruded Strip Gauge: 0.03” – 0.12” (0.75mm – 3.0mm)

- Extruded Strip Width: 10.0” (254mm)

- Angle Range: 18 to 90 degrees

- Finished Belt Width: 4.0” – 90.0” (101.6mm – 2286.0mm)

- Extruder Size: 4.5” (120mm) or 6″ (150mm) pin or smooth barrel

- Line speed example: 14” (355mm) belt @ 26 Degrees – 39,032 ft/day (11,897 m/day)

Tolerances:

- Belt Width (on cutter conveyor): ± 0.50 mm

- Strip Gauge: ± 0.05 mm

- Belt Angle: ± 0.25°

- Splice Accuracy: ± 0.20 mm

- Overlapped Cords: None

- Cord Spacing: ± 0.15 mm

- Cord Position (from center): ± 0.076 mm

- Splice Offset (dog ear): 0.50 mm

See also our Next Generation Extruded Steel Belt Systems for PCR (Passenger Car Radial) Tires & TBR (Truck / Bus Radial) Tires