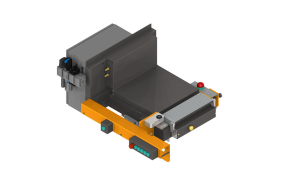

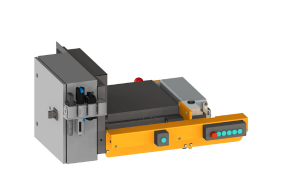

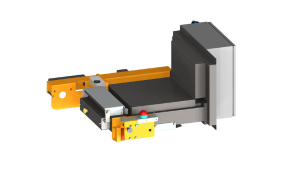

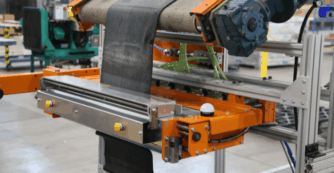

Introducing SafeSplice, Steelastic’s Cold Feed Extrusion Rubber Splicing Unit, engineered to protect your people and your production:

Safety First

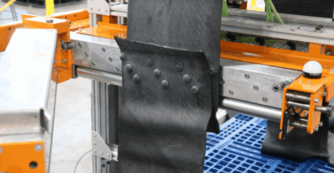

At Steelastic, safety always comes first. The new SafeSplice drastically reduces the need for operators to manually lift, cut, and splice heavy rubber sheets, tasks that carry significant risk and involve the use of hazards like Hot Knives or may require additional PPE. By automating the splice operation, SafeSplice keeps operators out of harm’s way creating a safer, more ergonomic working environment while reducing the risk of improper or insufficient rubber feed.

Elevate Quality & Consistency

Beyond safety, SafeSplice elevates production quality and consistency. The system automatically detects when to join the next feedstock of rubber and forms strong, precise splices with minimal overlap, maintaining a continuous flow to downstream equipment. Once loaded, no operator intervention is required ensuring smooth operation, superior splice quality, and greater line efficiency.

The SafeSplice Family

The SafeSplice family is available in three models, designed to accommodate the full range of common rubber feedstock configurations. Each unit integrates seamlessly with existing feed conveyors, or plant structures, for easy installation and operation:

- SafeSplice Mini 400mm. Ideal for smaller feedstock applications

- SafeSplice Pro 800mm. Optimized for the majority of feedstock applications

- SafeSplice Max 1000mm. Designed for the largest feedstock applications

Together, the SafeSplice range delivers scalable safety, precision, and performance, no matter the production demand.

Contact Steelastic to find out more!

Enhance the safety, quality, and efficiency of your extrusion lines. Contact Steelastic or fill out the form above to find out more.